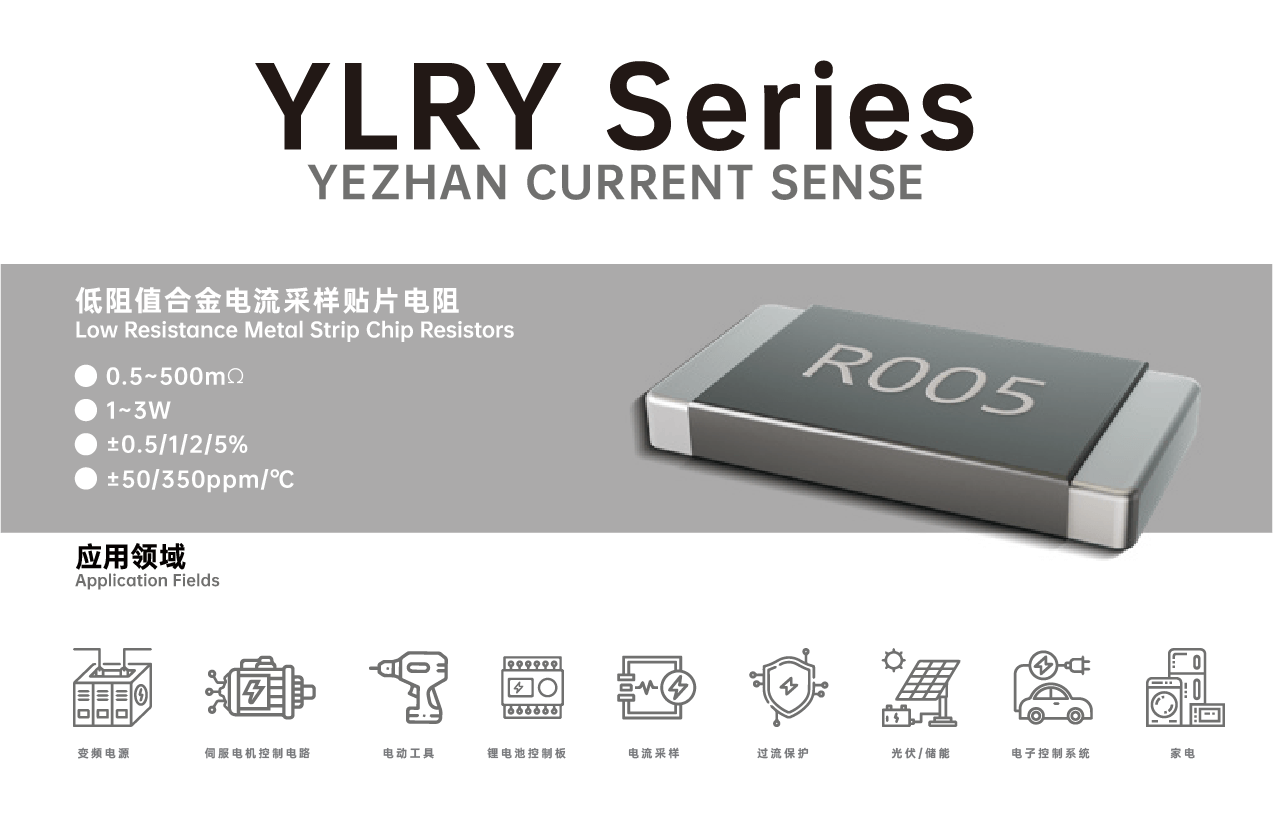

YLRY-0805 SERIES

YLRY-0805 series low-resistance alloy chip resistors are engineered for precision current sensing in demanding automotive and industrial applications. Utilizing advanced electron-beam welding technology, these components offer high power (0.5W) and low TCR (±50 ppm/℃) with resistance options from 3-40mΩ. Supported by robust production capacity and substantial inventory, we ensure reliable, high-volume supply for global clients seeking durable SMD resistor solutions.

APPROVAL SHEET

YLRY-0805 SERIES

Low Resistance Metal Strip Chip Resistors

Version | Date | Description of amendment | Draft | Checked |

A1.0 | 06-Jun-2025 | First edition release | 黄文强 | 王磊 |

1.Product Description

Product name:YLRY-0805 series

Description:YLRY-0805 series alloy chip resistors provide precise current sensing with low TCR and high power, ideal for automotive and industrial applications.

1.1 Part Number Explanation

The part number of the high power precision resistor is identified by the type name, power, tolerance, size and resistance value.

Example: YLRY05-W2-10F

Type | Size | Power | Resistance | Tolerance |

YLRY | 05=0805 | W2=0.5W | 10=10mΩ 0= 0mΩ |

D=±0.5% F=±1% G=±2% J=±5% Z=0mΩ

|

(1) Type name: YLRY series

(2) Size:05=0805;

(3) Power Rating:W2=0.5W;

(4) Resistance:10=10mΩ;0= 0mΩ

(5) Tolerance:D=±0.5%;F=±1%;G=±2%;J=±5%;Z=0mΩ

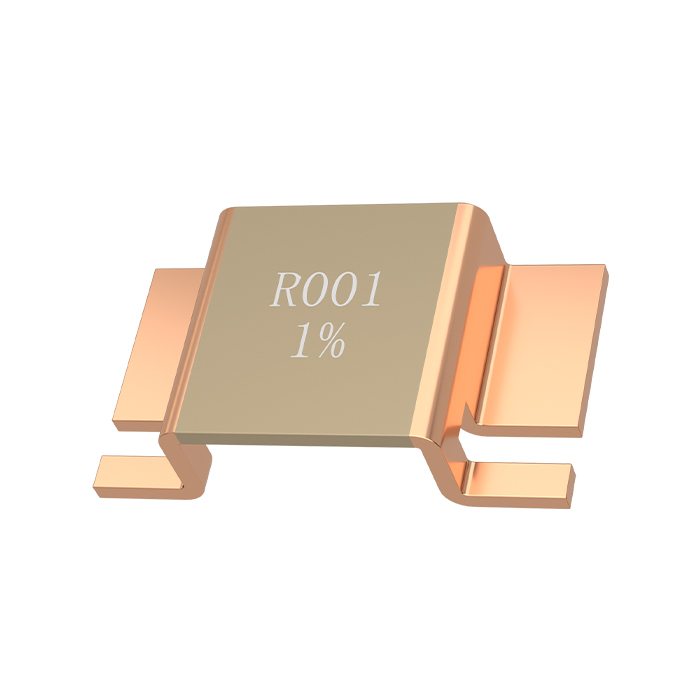

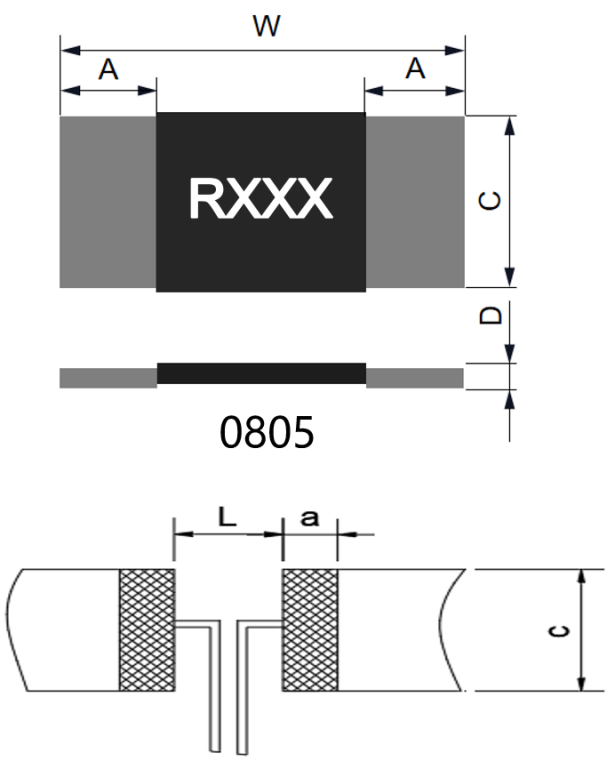

1.2 Products & Recommend Pad Dimension

Type | Resistance | W±0.2 | C±0.2 | A±0.2 | D±0.2 | L | a | c |

YLRY05 | 0 & 3~40mΩ | 2.0 | 1.25 | 0.35 | 0.5 | 1 | 1 | 1.5 |

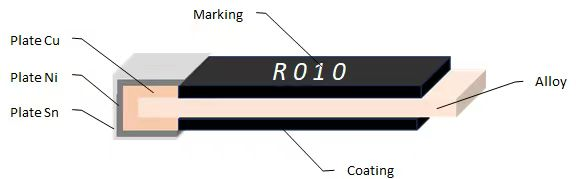

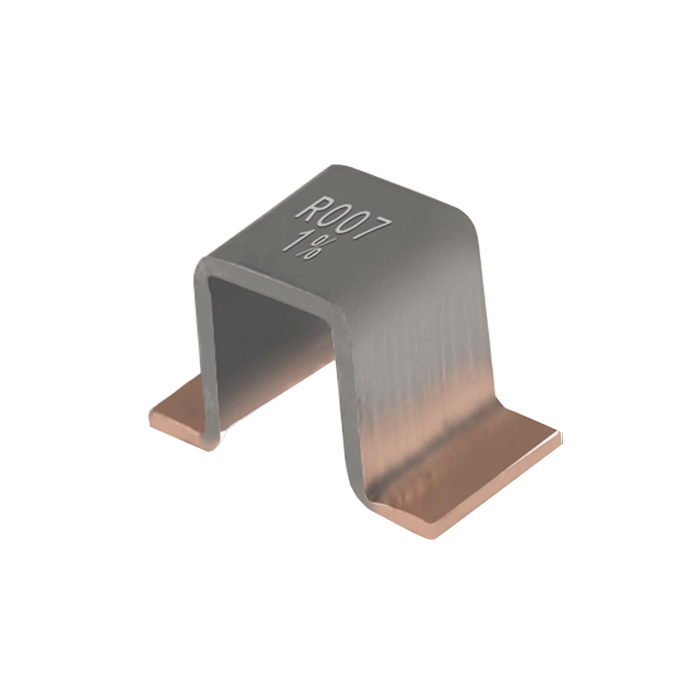

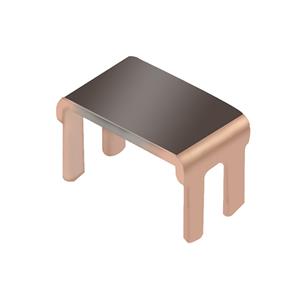

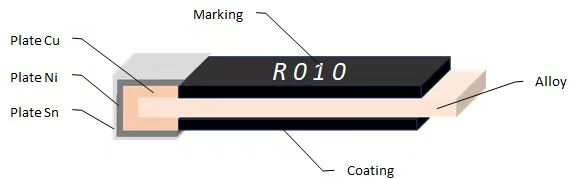

1.3 Item Construction

Electron-beam welded constructions

2. Standard Electrical Specifications

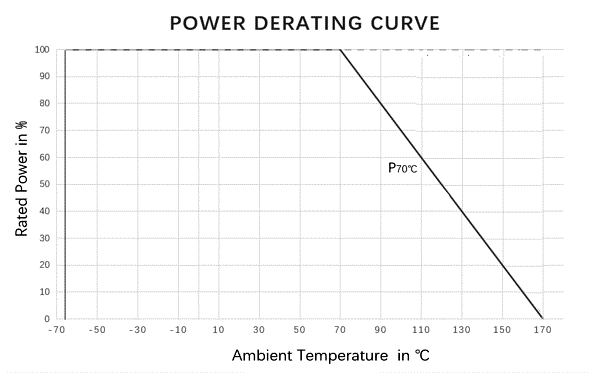

Type | Rated Power (W) | Resistance | Resistance Tolerance (%) | TCR① (ppm/℃) | Operating Temperature (℃) |

P70℃ | |||||

YLRY05 | 0.5 | 3~40 | D: ±0.5% F:±1% G:±2% J:±5% | ±50 | -55℃~170℃

|

Jumper | Rated Power (W) | Resistance | Resistance Tolerance (%) | Max Rated Current (A)

| Operating Temperature (℃) |

P70℃ | |||||

YLRY05 | 0.5 | ≤0.2mΩ | Z:0mΩ Jumper | 35 | -55℃~170℃

|

① TCR(ppm/℃):Test was conducted from 20℃ to 120℃ while 20℃ worked as the reference.

3. Endurance Test

Items | Test Method (Refer to IEC 60115,60068;JIS-C 5201-1)

| Specifications and Requirements |

Temperature coefficient (TCR) Short Time Overload | Resistance values were measured at 25℃(T1, R1) and 125℃(T2, R2), and TCR was calculated as (R2-R1)/ (R1 (T2-T1)) *10^6 5 times rated power, maintain 5s | Refer to TCR specifications for physical features △R≤ ±(1%+0.05mΩ) |

Insulation resistance | Apply 100V±15V DC voltage between electrode and substrate, hold for 60 seconds, then measure insulation resistance | > 100 MΩ |

Withstand voltage | An alternating current with an effective value of the maximum overload voltage is applied between the electrode and the substrate at a rate of approximately 100V/S, maintaining 60±5s | No breakdown or arc |

solderability | 245℃±5℃ tin tank, hold 2s±0.5s | At least 95% of surface area of electrode shall be covered with new solder |

Resistance to Soldering Heat | 270℃±5℃ tin tank, hold for 10s±1s | △R≤± (0.5%+0.05mΩ),no visible damage |

Bending test | Bending distance 2mm, hold time 60s±5s | △R≤±(0.5%+0.05mΩ)no mechanical damage |

Solvent resistance | Isopropanol (IPA) at 23℃±5℃ for 10 hours | No obvious damage to appearance |

High Temperature Exposure | 170℃±2℃, 1000H, stand for 1H, test the resistance value | △R ≤± (1.0%+0.05mΩ) |

Low Temperature Exposure | -55℃±2℃, 1000H, stand for 1H, test the resistance value | △R ≤± (0.5%+0.05mΩ) |

Rapid change of Temperature | -55℃ 30 minutes ~ normal temperature 5 minutes ~155℃ 30 minutes, 1000 cycles | △ R ≤± (0.5%+0.05mΩ) |

Load Life | 70℃±2℃, 1000 hours, rated power, 1.5 hours on / 0.5 hours off | △R ≤± (1.0%+0.05mΩ) |

Moisture with Load | 85℃±2℃, 85%±3%RH, 1000 hours, rated power, 1.5 hours on / 0.5 hours off | △R≤± (1.0%+0.05mΩ) |

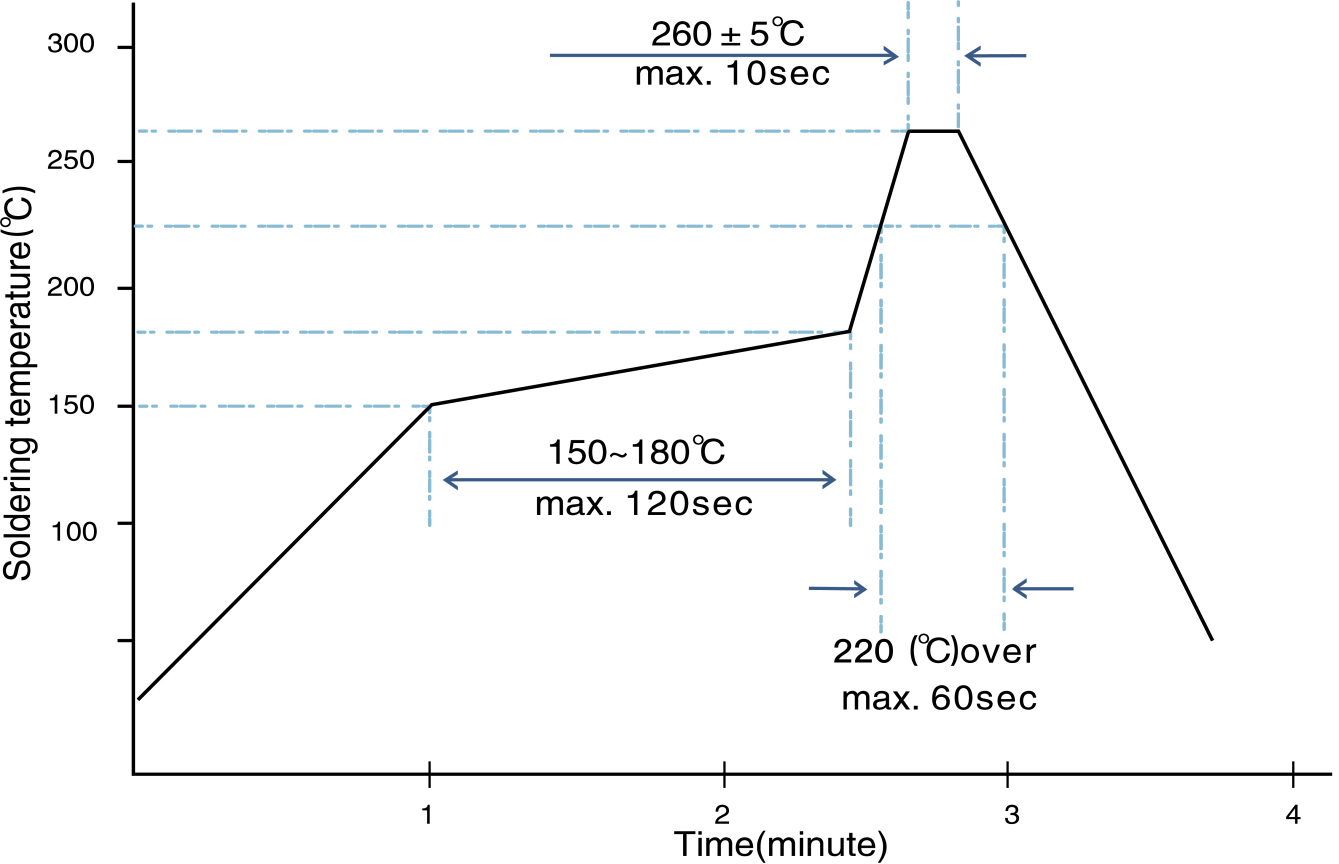

4.Solder Reflow Temperature Condition

5.Power Derating Curve

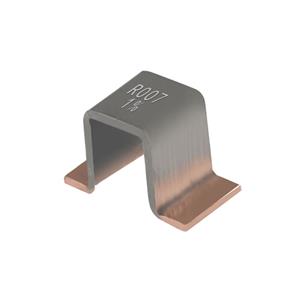

6.Marking

White Printed Marking:

· All the products marking are 3 or 4 digits. ‘R’ designates the decimal location in ohms

E.g., :

· 0= 0mΩ jumper; 5mΩ=R005; 50mΩ=R050

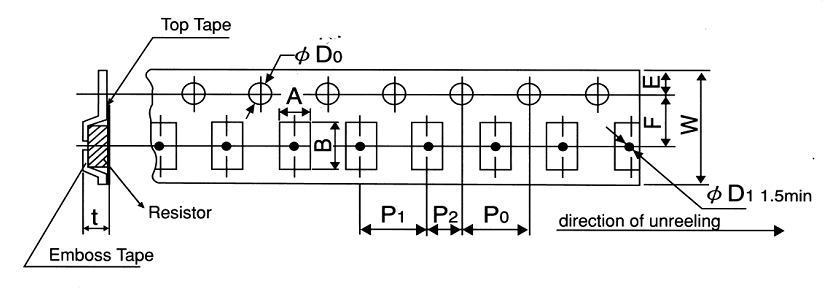

7.Packing

Storage Conditions: Storage Conditions: Temperature:5℃~35℃, Humidity:40%~75%

Storage life: 1 year;

Packing Type:Embossed Plastic Tape

Type | A± 0.05 | B± 0.1 | W± 0.2 | F± 0.05 | E± 0.1 | P1± 0.1 | P2± 0.05 | P0± 0.05 | D0± 0.1 | t± 0.1 | Qty /reel |

YLRY 05 | 1.65 | 2.4 | 8.0 | 3.5 | 1.75 | 4 | 2 | 4 | Φ1.5 | 0.8 | 5000 |

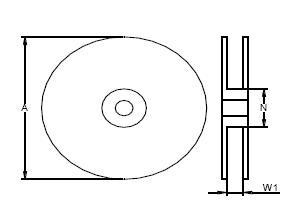

8.Reel & Tape Specifications

Unit/mm

Type | A | N | W1 |

YLRY05 | 178±2 | 60±1 | 9±0.3 |

This document is a product specification. Contents are subject to change without notice.

© 2026 THUNDER PRECISION RESISTOR CO.,LTD. All Rights Reserved.