precision resistors

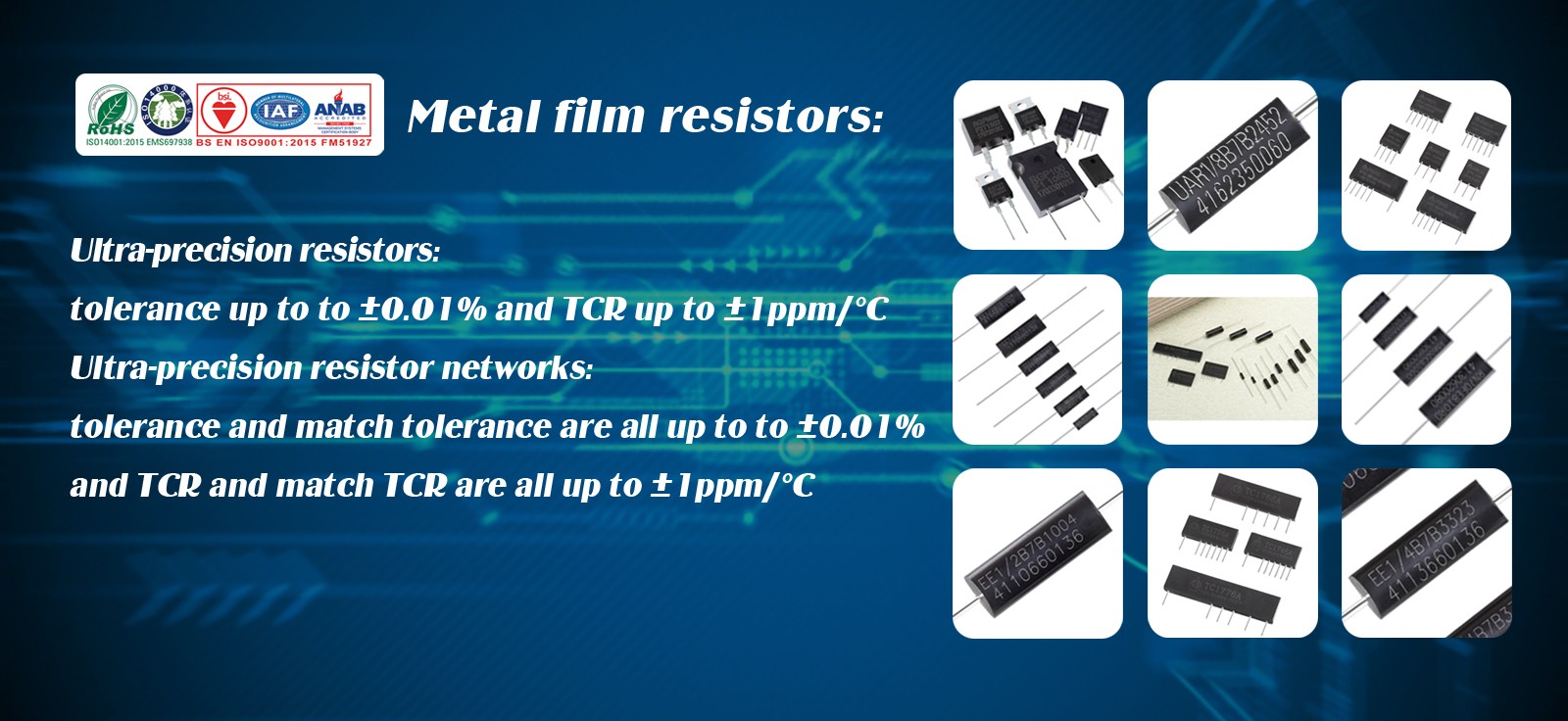

Thunder Precision Resistor Co., Ltd. is 29 years experienced professional manufacturer of high precision resistors, ultra-precision resistor networks, precision MELF resistors, precision wire wound resistors, current shunts and lot of special resistors in China. The quality of the products is always the first priority in Thunder Precision Resistors and that is our quality policy. BSI issued ISO9000 Quality Management Certificate to Thunder Precision Resistor Co., Ltd. in 1998 and upgraded it in June 2016 to ISO9001:2015. Our company has been issued the Environmental Management Systems Certificate ISO14001:2015 by British Standards Institution (BSI) in 2018. Our company has been issued the Automotive Quality Manage System IATF16949:2016 certificate by British Standards Institution (BSI) in 2019.

-

26-07-2022

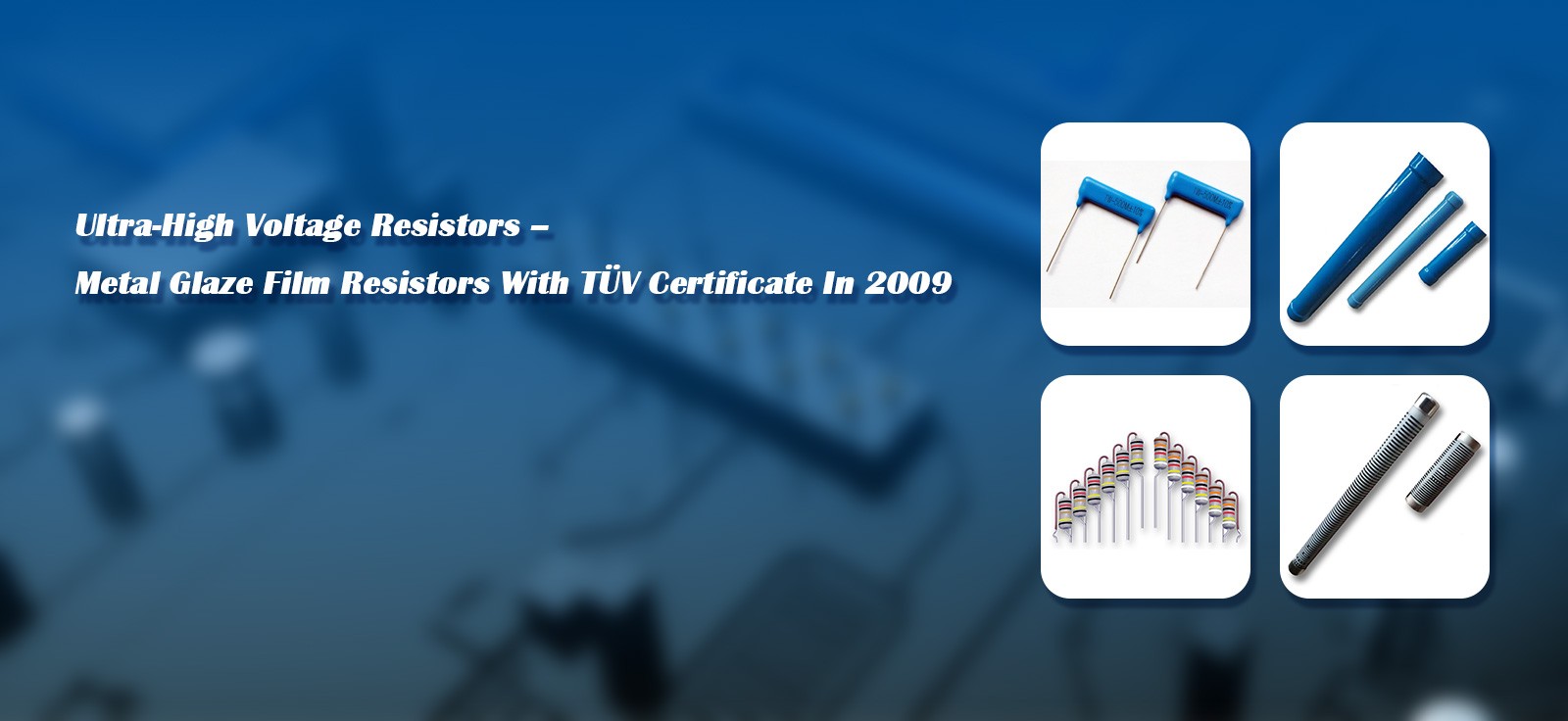

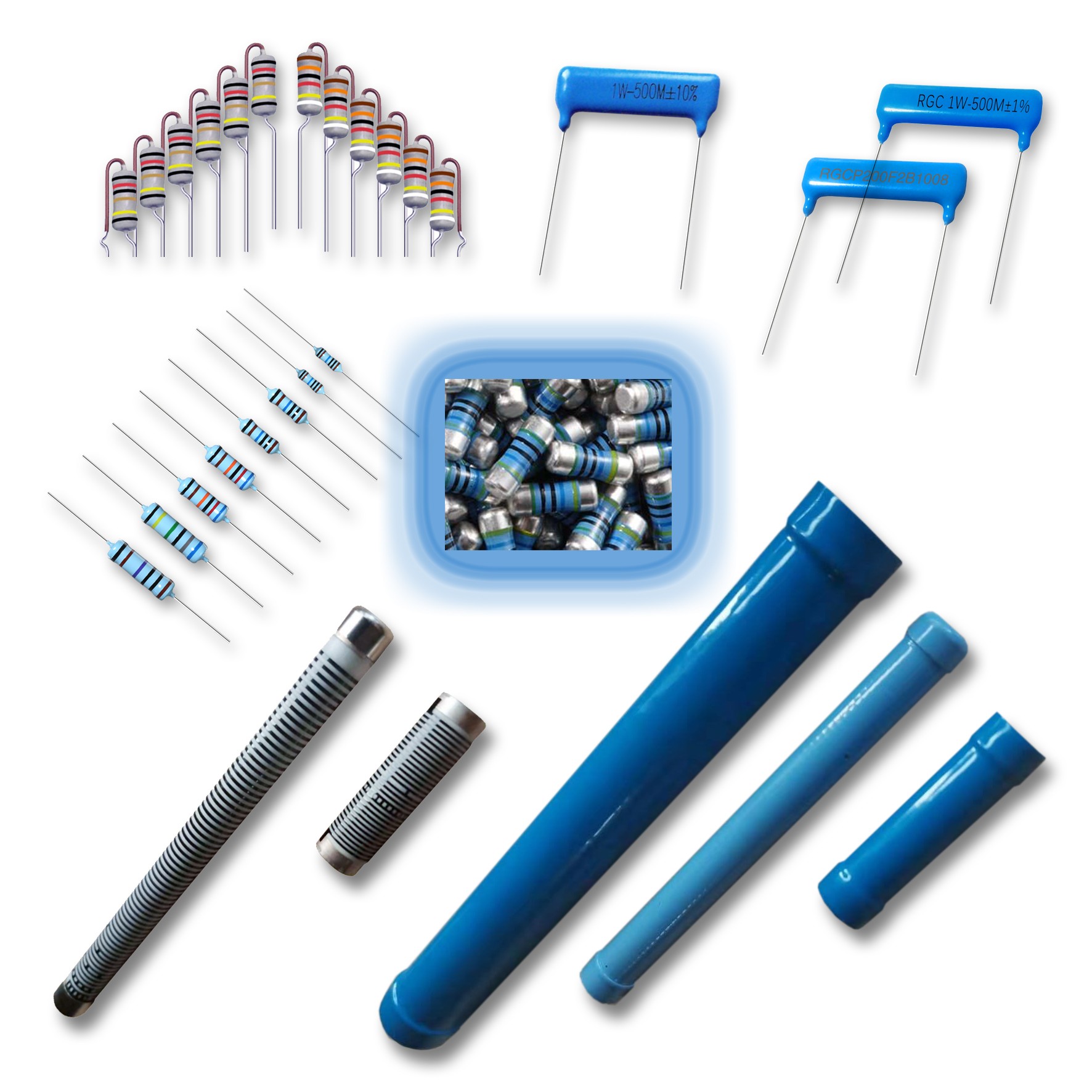

Thunder Precision Resistor Co., Ltd. applied RoHS and Reach Test to guarantee all materials used in the products as well as the packing materials meet the Restriction of Hazardous Substances and REACH/SVHC requests. Thunder Precision Resistor Co., Ltd. requested all the material suppliers to provide RoHS and REACH/SVHC test reports annually and applied the RoHS and REACH/SVHC tests our selves occasionally to make sure all materials are under control even the packing materials. Thunder Precision Resistor Co., Ltd. makes high precision resistors and special resistors, such as high power precision wire wound resistors up to 150W with temperature coefficient low than 15ppm, high resistance resistors up to 10G Ohm with temperature coefficient of resistance lower than 25ppm/℃, ultra-precision resistors with tolerance up to 0.005% and temperature coefficient lowen than 1ppm/℃, high resistance wire wound resistors with resistance up to 100k Ohm, etc.

-

05-02-2022

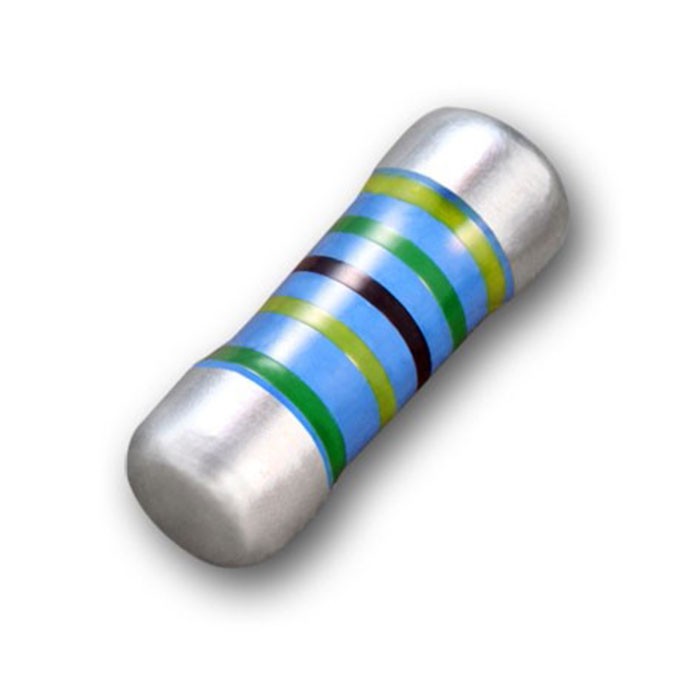

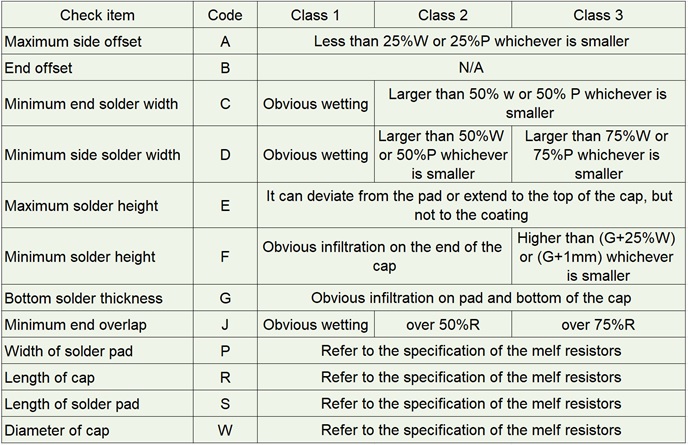

晶圆电阻(melf resistors) 焊接效果目视检查项目与合格判据表 Visual inspection items and qualification criteria of welding effects for melf resistors extracted from IPC-A-610G by Thunder Precision resistor Co., Ltd.

-

25-02-2022

Hackers intercepted Thunder Precision Resistor's users' emails and sent them to us after modifying the email website suffix. All the information we replied to these email was rejected but we didn't received the failure info. Hackers intercepted our replied email and then tampered with the bank information, sent these fake info to our users, resulting in the failure of users' payment for several times. Please pay attention to the mail address you replied to check it is the normal one or different from the normal one. Thunder Precision Resistors will pay attention to those email contain certain importance info such ad bank payment info and the contract info, etc.

-

23-02-2022

8.3.3.3 Visual inspection 3:Minimum end solder width of MELF resistors after reflow soldering minimum end solder width of melf resistors after reflow soldering in larger than 50% of the diameter of the resistors or larger than 50% of the width of the solder pad. the wider the solder width the better the solder strongth. the most important of the the requirement of getting wide solder width at the end of melf resistors is the sufficient amount of tin paste on the solder pads. minimum end solder width of melf resistors after reflow soldering in larger than 50% of the diameter of the resistors or larger than 50% of the width of the solder pad. the wider the solder width the better the solder strongth. the most important of the the requirement of getting wide solder width at the end of melf resistors is the sufficient amount of tin paste on the solder pads.

Precision Resistors

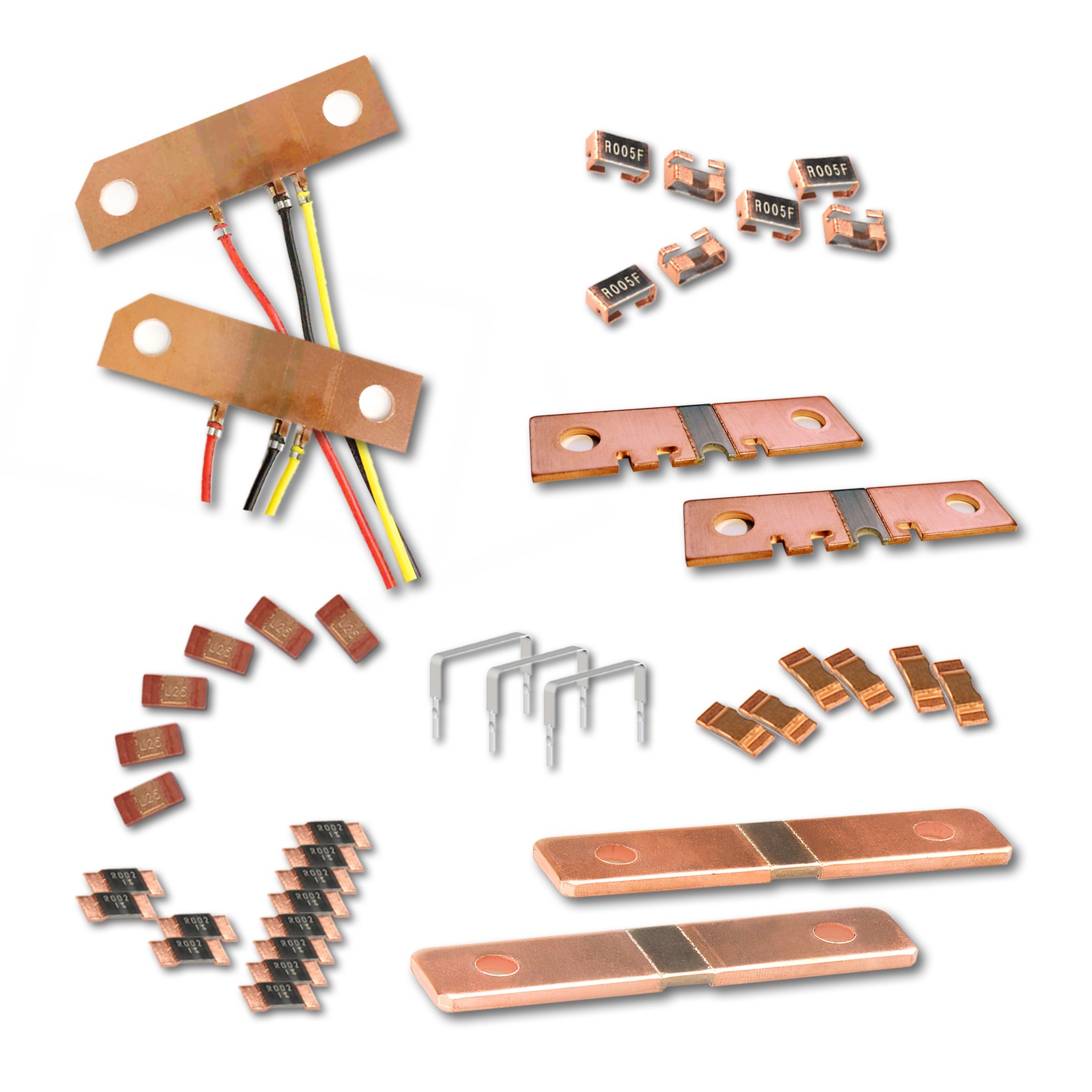

Alloy Shunt Resistor 4312 20w Low Tcr

Manganin Alloy Shunt Resistor 5w Low Tcr

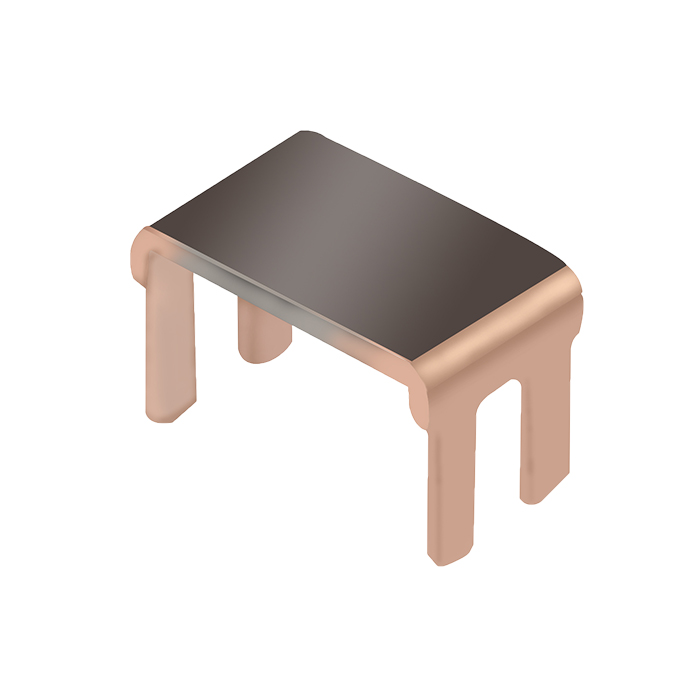

High Precision Alloy Shunt 3mΩ To 10mΩ

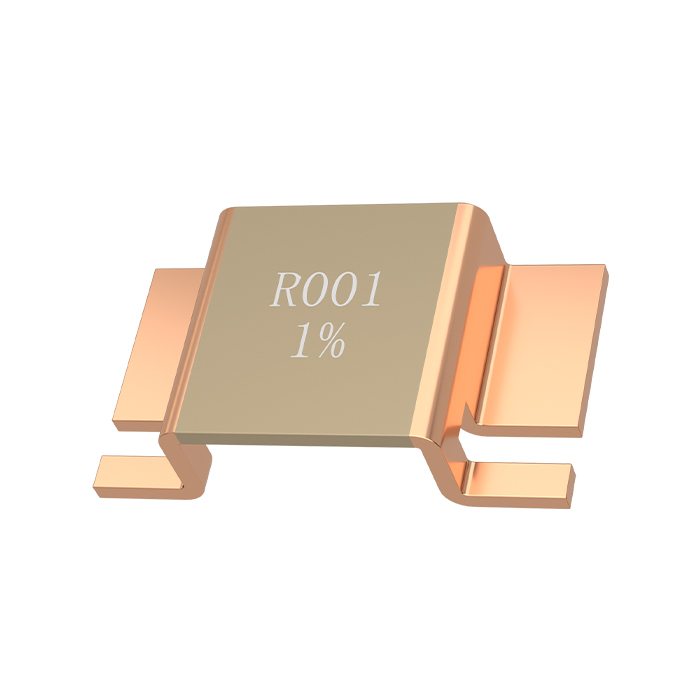

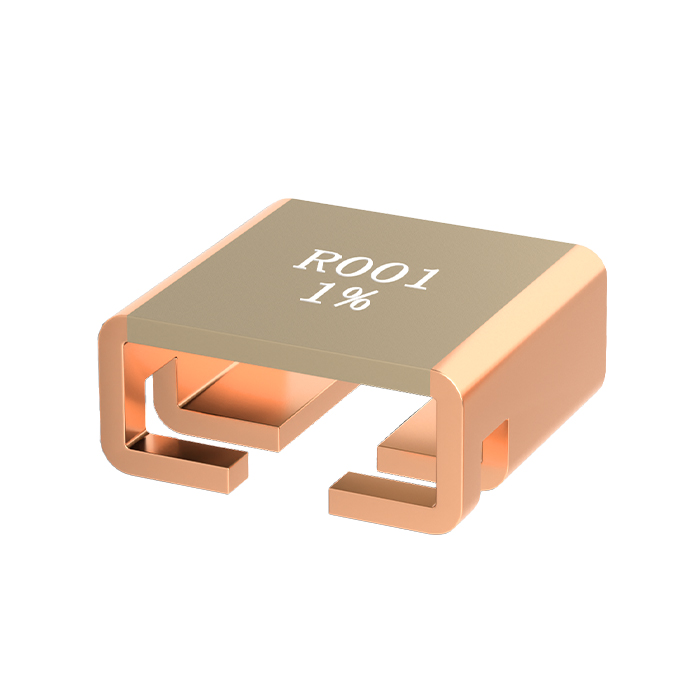

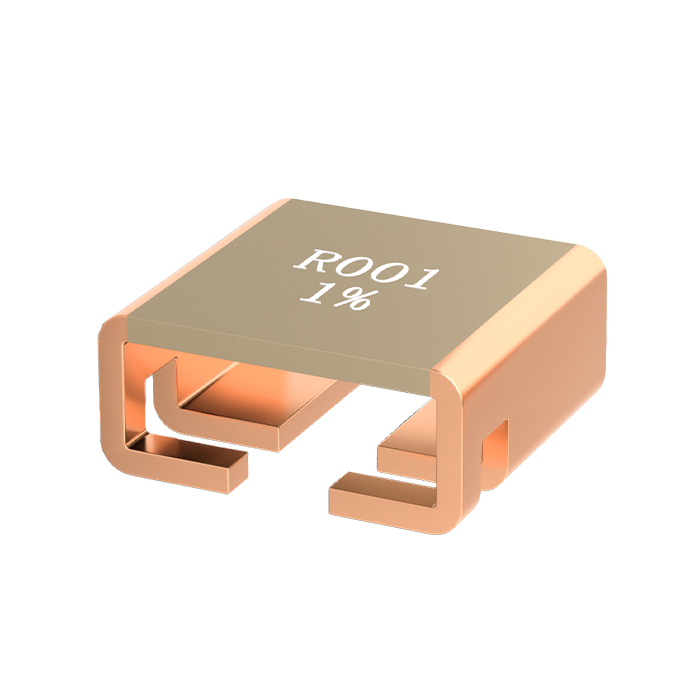

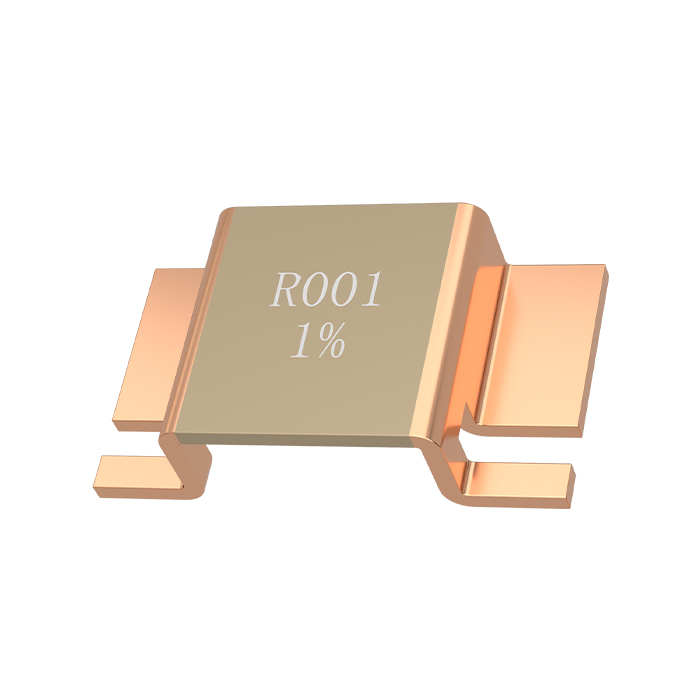

4-terminal Shunt Resistor Smd Aec-q200

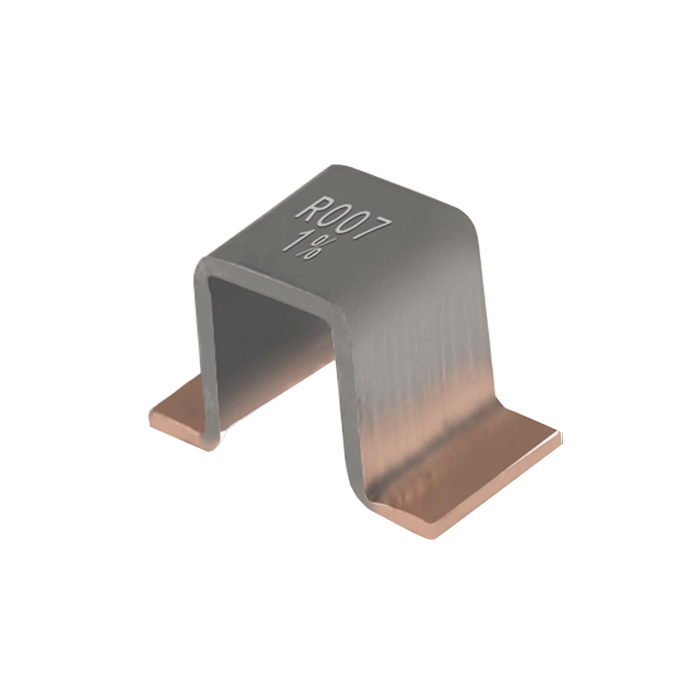

4-terminal Shunt Resistor 4026 12w Aec-q200

4-terminal Shunt Resistor Sbbp 12w Aec-q200

Alloy Shunt Resistor 3921 9w Aec-q200

Manganin Shunt Resistor 2512 6w Aec-q200

Alloy Shunt Resistor 2512 5w Aec-q200

Alloy Shunt Resistor 3920 9w Aec-q200

Current Sensing Resistor 2512 3w Aec-q200

Alloy Chip Resistor 0805 Low Resistance Current Sensing

Ylry-2512 1206 Chip Resistor

Ylry-2010 Metal Strip Chip Resistor

Low Resistance Metal Strip Chip Resistors

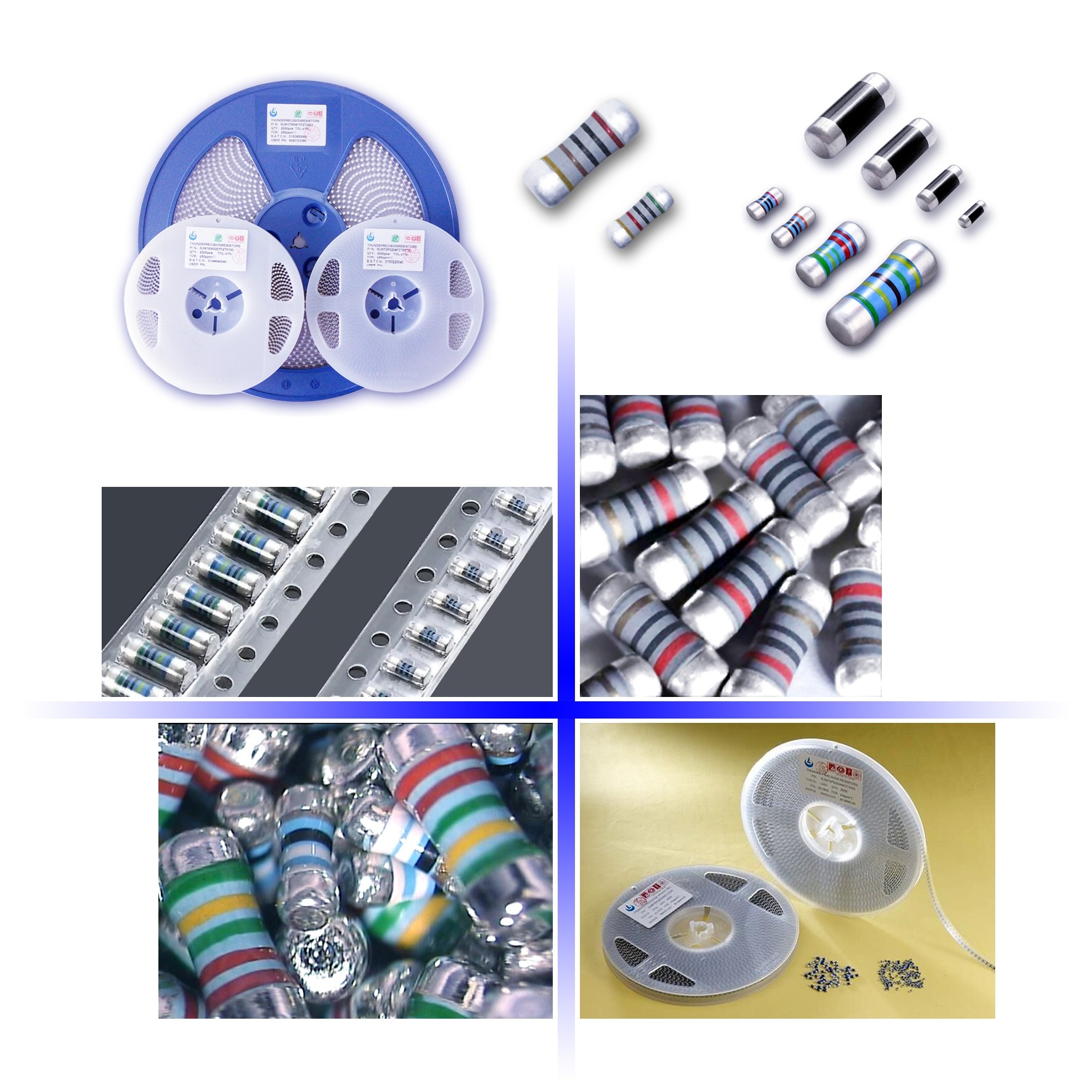

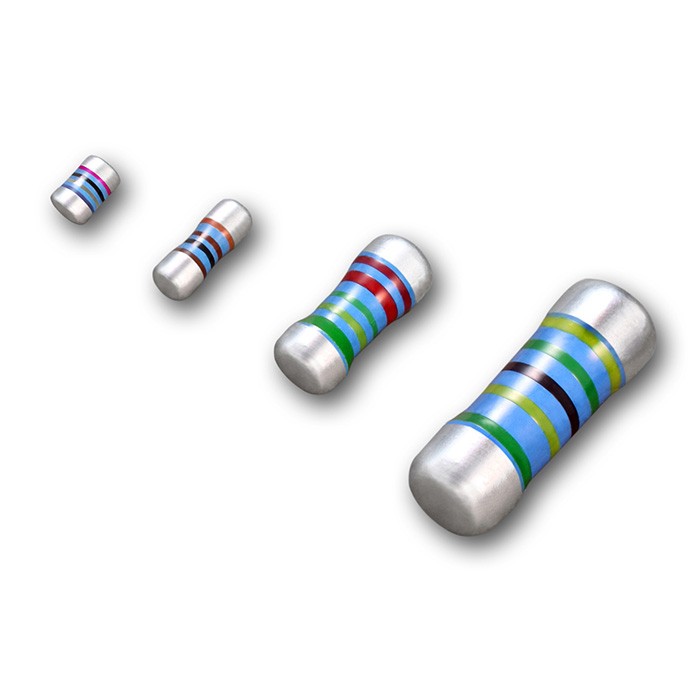

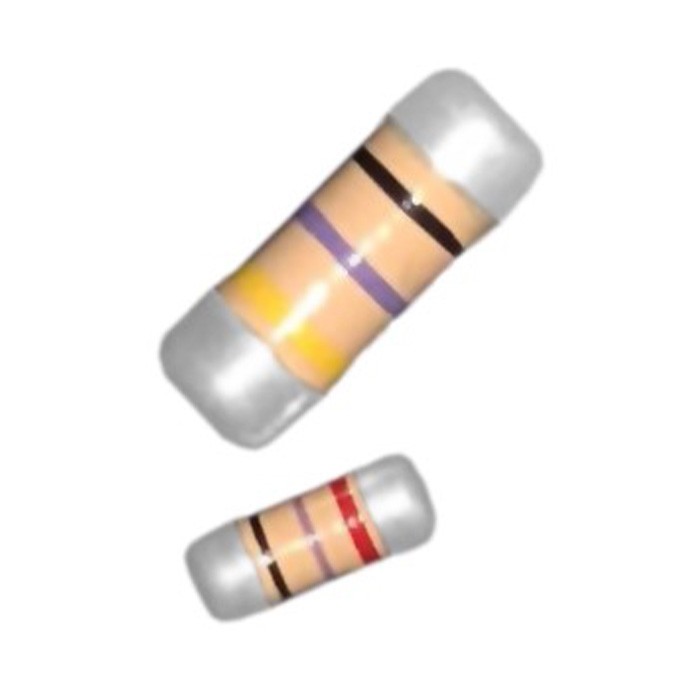

Precision Melf Resistors

High Precision Melf Resistors

Glaze Film Melf Resistors

Precision Wirewound Resistors