-

The tested product has a pulse energy resistance of 270J/cm³ (Effective size) and total 30kJ single pulse withstand energy. The resistors the product shows perfect non-inductive performance of nH level in the ultra-high frequency circumstances. The extremely high pulse withstand voltage of the module is up to 24,000V in oil and surge pulse withstand voltage is up to 170kV. The modules is compliant to RoHS directive 2011/65/EU and REACH (EC No. 1907/2006)) (last updated: 27/06/2018).

-

SGShad made the wetting balance tests to prove the perfect solder-ability of the precision melf resistors made by thunder precision resistors. The result of the test declared the high quality of the precision melf resistors made by thunder precision resistors.

-

Thunder Precision Resistor Co., Ltd. had made the wetting balance tests to prove the perfect solder-ability of the precision melf resistors made by thunder precision resistors. The test was made by SGS and the result of the test declared the high quality of the precision melf resistors made by thunder precision resistors.

-

0407-2022

what is MELF Resistors

-

Fusible wire wound resistors FEATURES · Advanced alloy wire technology · Fusible less than 60 seconds when against 25 times power abnormal applied or according to customer’s request · Reliable in pulse / transient / abnormal surge applications · Non-inductance winding available upon request · Flame retardant coating

-

2306-2022

Wirewound resistor

-

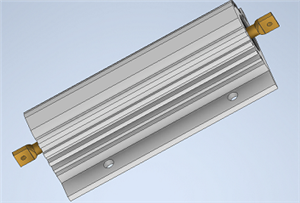

FEATURES · Advanced Isabellenhütte alloy technology · Very low TCR: lower than ±10ppm/℃. · Tolerance up to ±0.1% · Excellent overall stability: Class 1 · Very low noise and voltage coefficient · Non-inductance winding available under request · Perfect pulse loading capability: over 25 times rated power loading · Extremely high dielectric strength: stand over 3000VDC insulation voltage Thunder Precision Resistor Co., Ltd has been making precision wire wound resistors with tiny size housed in aluminium shell.

-

Thunder Precision Resistor Co., Ltd. disclosed the process and preparation methods of making a new kind of UHF RF resistors: (1) Take a certain mass of nano silicon carbide with a particle size of 20nm ~ 50nm and disperse it in 95% ethanol with a mass multiple of 5 ~ 8 times, and then add nano alumina with a particle size of 20nm ~ 50nm with a mass of 2 ~ 3 times of nano silicon carbide to fully disperse it; (2) Add silane coupling agent dl602 with 2% ~ 3% mass of nano silicon carbide, fully stir until the system thickens, and then add organic Polyborosilazane iota-9120 with 0.3 ~ 0.5 times mass of nano silicon carbide to fully disperse; (3) in air atmosphere, the mixture of step 2 (step 2) was desiccant and cured by spray drying method, and the modified filler was prepared.

-

0304-2022

New invention patent approved

Thunder Precision Resistor Co., Ltd. had disclosed an invention of an ultra-high frequency RF resistor and a production method thereof. The new invention patent had be approved and issued. The diamond substrate is used as the substrate material, the composite heat dissipation substrate is used to improve the heat dissipation efficiency, and the special packaging material is used to further improve the heat dissipation performance of the RF resistor. The production method uses liquid nitrogen cooling to control the temperature rise of laser resistance adjustment, laser seamless welding and laser cutting, so as to prevent the resistance value variation of the resistance layer of the RF resistor during the production process.

-

1503-2022

Melf resistors